How Machine Learning is Transforming Predictive Maintenance in Manufacturing

How Machine Learning is Transforming Predictive Maintenance in Manufacturing

Introduction

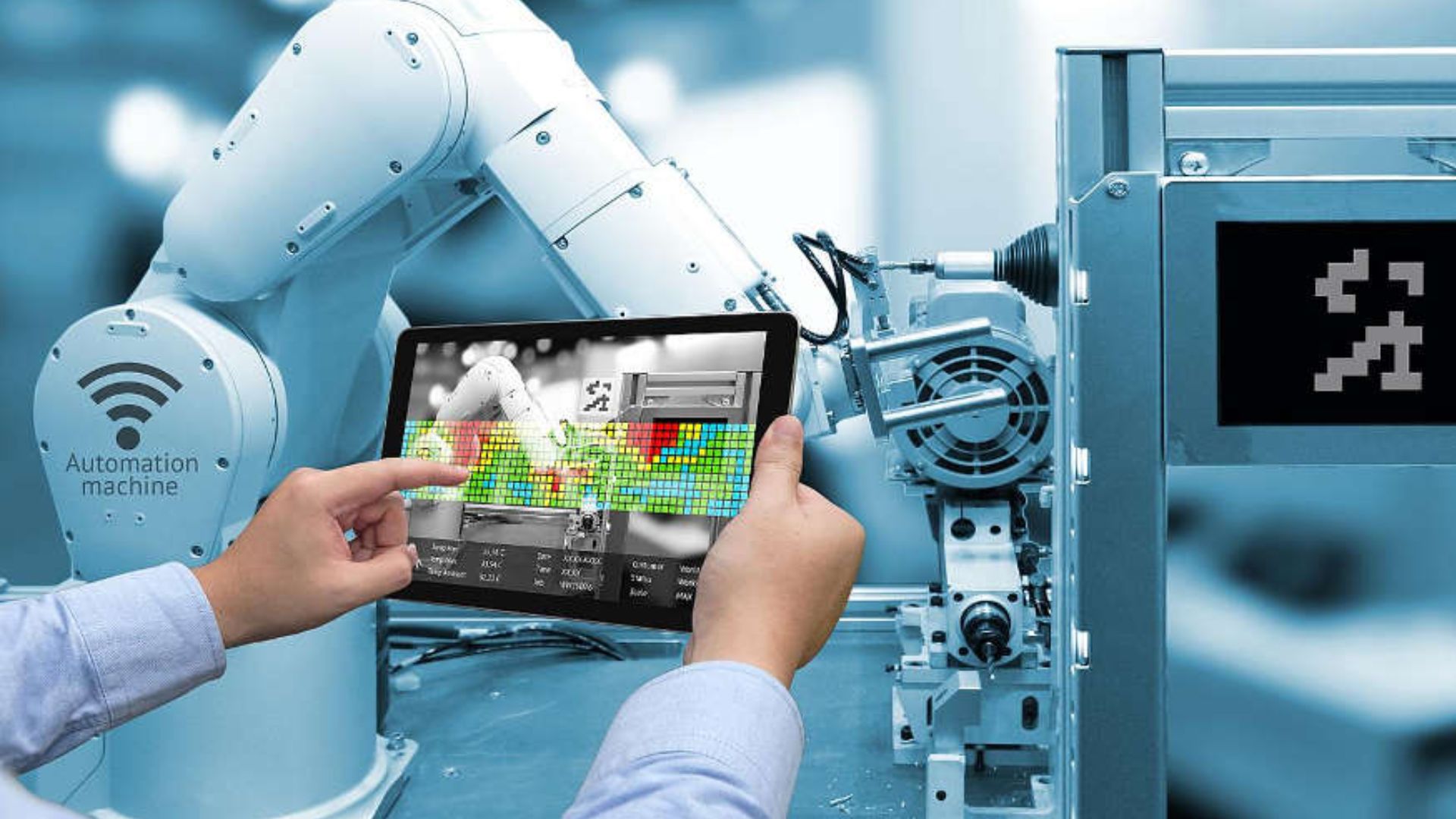

In the rapidly evolving manufacturing sector, efficiency and productivity are paramount. One of the critical areas where technology is making a significant impact is maintenance strategies. Traditional maintenance approaches, such as reactive and preventive maintenance, often lead to unexpected downtime and increased operational costs. Enter Machine Learning (ML), a subset of Artificial Intelligence (AI), which is revolutionizing predictive maintenance. By leveraging ML algorithms, manufacturers can predict equipment failures before they occur, optimize maintenance schedules, and enhance overall operational efficiency. This article explores how ML is transforming predictive maintenance in manufacturing, the technologies involved, benefits, challenges, and future prospects.

The Evolution of Maintenance Strategies

From Reactive to Predictive Maintenance

Maintenance strategies have evolved over time:

- Reactive Maintenance: Also known as “run-to-failure,” this approach involves fixing equipment after it breaks down. While it requires minimal planning, it can lead to unexpected downtime and higher costs.

- Preventive Maintenance: Scheduled maintenance at regular intervals aims to reduce the likelihood of failures. However, it doesn’t account for actual equipment conditions, potentially leading to unnecessary maintenance or unexpected breakdowns.

- Predictive Maintenance: Utilizes real-time data and analytics to predict equipment failures before they happen, allowing for maintenance only when necessary.

The Role of Machine Learning

Machine Learning enhances predictive maintenance by analyzing vast amounts of data from sensors and equipment. ML algorithms detect patterns and anomalies, providing insights into equipment health and predicting potential failures with high accuracy.

Machine Learning Technologies in Predictive Maintenance

Data Collection and IoT Sensors

The foundation of ML-driven predictive maintenance is data:

- Internet of Things (IoT) Sensors: Installed on equipment to collect data such as temperature, vibration, pressure, and sound.

- Real-Time Monitoring: Continuous data collection provides a comprehensive view of equipment performance.

Data Processing and Feature Extraction

Before data can be used for ML models, it needs processing:

- Data Cleaning: Removing noise and irrelevant information to ensure data quality.

- Feature Extraction: Identifying relevant variables that influence equipment performance.

Machine Learning Algorithms

Various ML algorithms are used for predictive maintenance:

Supervised Learning

- Regression Models: Predict continuous outcomes like remaining useful life (RUL) of equipment.

- Classification Models: Categorize equipment states into “normal” or “faulty.”

Unsupervised Learning

- Anomaly Detection: Identifies patterns that deviate from normal behavior without prior labeled data.

- Clustering: Groups similar data points to detect patterns and anomalies.

Deep Learning

- Neural Networks: Handle complex patterns in large datasets, improving prediction accuracy.

- Recurrent Neural Networks (RNNs): Suitable for time-series data analysis common in equipment monitoring.

Cloud Computing and Edge Analytics

Processing and analyzing data require significant computational resources:

- Cloud Computing: Provides scalable resources for data storage and ML model training.

- Edge Analytics: Processes data near the source (on the equipment), reducing latency and bandwidth usage.

Benefits of ML-Driven Predictive Maintenance

Reduced Downtime and Increased Equipment Availability

By predicting failures before they occur, maintenance can be scheduled proactively, minimizing unexpected equipment downtime and ensuring continuous production.

Cost Savings

Optimizing maintenance schedules reduces unnecessary maintenance activities and extends equipment life, leading to significant cost reductions in maintenance operations and capital expenditures.

Improved Safety

Preventing equipment failures enhances worker safety by reducing the risk of accidents caused by malfunctioning machinery.

Enhanced Decision-Making

ML provides data-driven insights, enabling maintenance teams to make informed decisions about maintenance priorities and resource allocation.

Optimized Inventory Management

Predictive insights help in managing spare parts inventory efficiently by anticipating the need for replacements, reducing inventory holding costs.

Challenges in Implementing ML for Predictive Maintenance

Data Quality and Quantity

Effective ML models require large volumes of high-quality data:

- Data Silos: Disparate systems and data formats can hinder data integration.

- Incomplete Data: Missing or inaccurate data affects model accuracy.

Technical Expertise

Implementing ML solutions necessitates specialized skills in data science, ML algorithms, and domain knowledge in manufacturing processes.

Integration with Existing Systems

Seamless integration with current manufacturing execution systems (MES) and enterprise resource planning (ERP) systems can be complex and costly.

Initial Investment Costs

Upfront costs for sensors, data infrastructure, and ML development can be significant, requiring justification through return on investment (ROI) analysis.

Data Security and Privacy

Collecting and transmitting equipment data raises concerns about cybersecurity. Manufacturers must implement robust security measures to protect sensitive data.

Case Studies: ML in Action

Siemens’ Predictive Maintenance Solutions

Siemens utilizes ML algorithms to monitor and analyze data from industrial equipment:

- Wind Turbines: Predictive analytics forecast potential failures, optimizing maintenance schedules and reducing downtime.

- Rail Systems: ML models predict component wear and failures in trains, enhancing safety and reliability.

General Electric’s (GE) Digital Twin Technology

GE employs digital twins—virtual replicas of physical assets—to simulate and predict equipment performance:

- Aircraft Engines: Real-time monitoring and ML analytics predict maintenance needs, reducing in-flight failures.

- Power Plants: Predictive maintenance improves efficiency and reduces operational costs.

Ford Motor Company’s Predictive Maintenance

Ford implemented ML algorithms in their manufacturing plants to monitor equipment health:

- Assembly Line Robots: Predictive models detect anomalies in robot operations, preventing breakdowns.

- Cost Reduction: Achieved significant savings by reducing unplanned downtime and maintenance costs.

Future Prospects of ML in Predictive Maintenance

Integration with Artificial Intelligence and IoT

The convergence of AI, ML, and IoT will further enhance predictive maintenance capabilities:

- Autonomous Maintenance: Systems that can self-diagnose and initiate maintenance actions without human intervention.

- Enhanced Connectivity: 5G technology will enable faster data transmission, supporting real-time analytics.

Advanced Analytics and Edge Computing

Edge computing will play a significant role in processing data locally:

- Reduced Latency: Immediate data processing enables quicker responses to equipment issues.

- Bandwidth Efficiency: Less data transmitted to the cloud reduces bandwidth requirements.

Customized ML Models

Development of more sophisticated ML models tailored to specific equipment and industry needs will improve prediction accuracy.

Collaboration and Standardization

Industry-wide collaboration will lead to the development of standards and best practices for implementing ML in predictive maintenance.

Strategies for Successful Implementation

Start with Pilot Projects

Begin with small-scale implementations to demonstrate value and learn from initial challenges before scaling up.

Invest in Training and Expertise

Develop internal capabilities by training staff or hiring experts in ML and data analytics.

Ensure Data Quality

Implement robust data management practices to ensure the integrity and reliability of data used for ML models.

Collaborate with Technology Partners

Work with experienced vendors or partners who specialize in ML solutions for manufacturing to leverage their expertise.

Focus on Change Management

Address organizational culture and employee adoption by communicating benefits and providing necessary support during the transition.

Conclusion

Machine Learning is fundamentally transforming predictive maintenance in manufacturing, offering unprecedented opportunities to enhance efficiency, reduce costs, and improve safety. By harnessing the power of ML algorithms and real-time data analytics, manufacturers can predict equipment failures before they occur, optimize maintenance schedules, and make informed decisions. While challenges exist, such as data quality and integration complexities, the benefits far outweigh the hurdles. As technology continues to advance, ML-driven predictive maintenance will become an integral part of smart manufacturing, driving the industry toward a more proactive and efficient future.